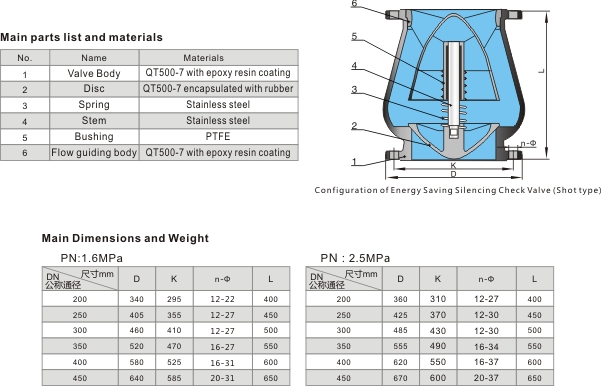

The Energy Saving Silencing Check Valve (Shot type) with flanged ends is a new generation of product developed by our company

based on the massive information and materials collected at home and abroad, and meanwhile through serious research and analysis

on the current applied similar products.

With a thorough consideration of the principle of hydromechanics, the valve body and disc are designed as a streamline

structure. Featured with low pressure loss, high flow capacity, strong cavitation and water hammer resistance, the valve

could completely meet the demands of modern piping networks, and become an ideal device for preventing flow from reversing

and reducing water hammer in modern piping networks.

Streamline and wide valve body design without blind bends, corners, and sharp protrusion for reducing flow resistance and noise.

Short closing distance travelled by the valve disc, reducing the closing time and decreasing the water hammer impact. Innerspring setup to ensure smooth and reliable movement of the valve disc, which will close automatically on condition of zero flow and prevent the flow from reversing.

The flow area from any point of the valve is larger or equal to the cross section area of the DN, so that the flow rate can keep basically reliable and the occurrence of eddy and cavitation are avoided which in turn greatly lower down the possibility of noise happening.

Small volume, light weight, and good appearance; installed in vertical, horizontal, slanted, and any other angle.

Both inner and outer surfaces of the valve body are electrostatically coated with epoxy resin powder which is environmentally

friendly and non―toxic to ensure strong corrosion resistance capacity and safety.